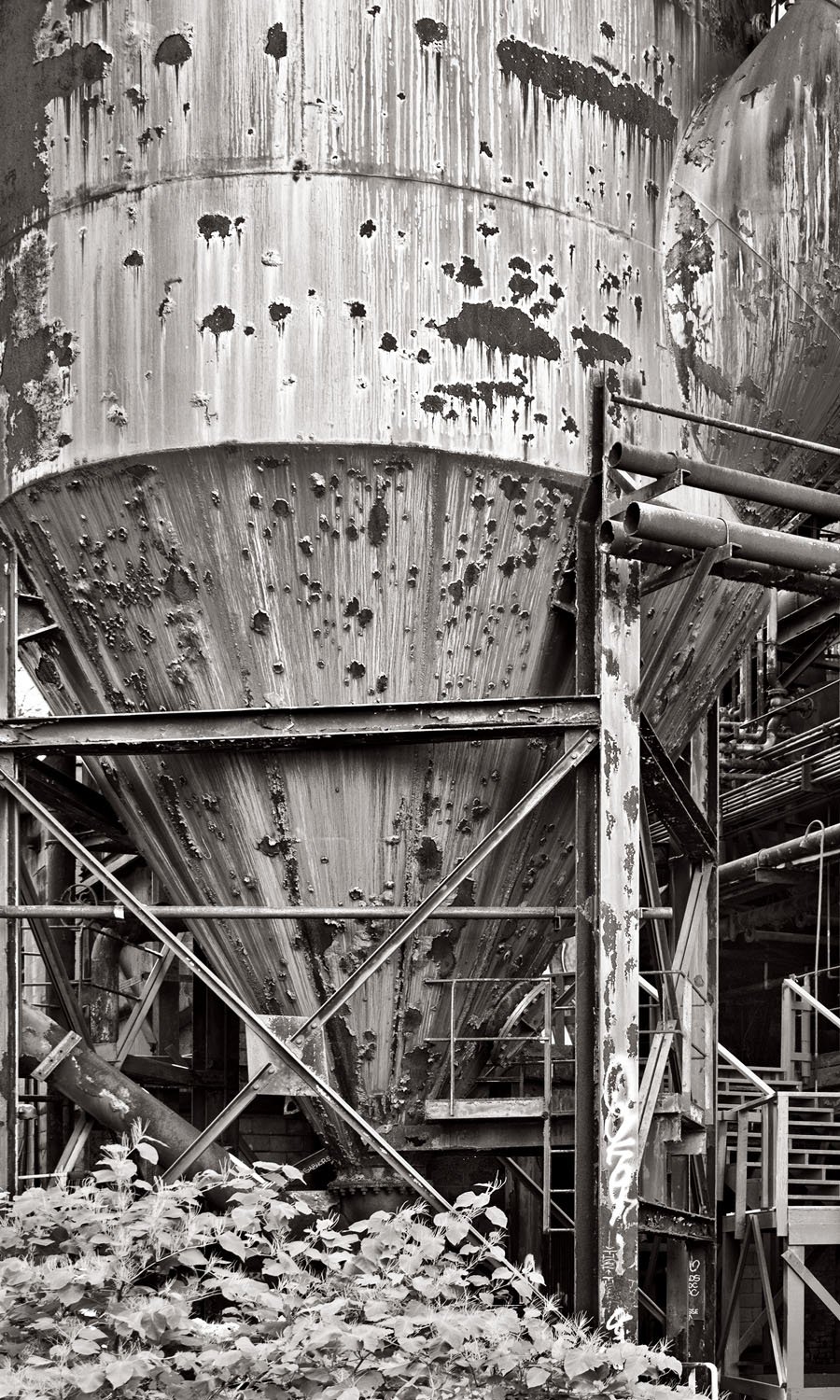

The Carrie Furnace I

A view of the outside of one of two remaining furnaces on the Carrie site. At one time there were seven such furnaces in operation at once. The audio clip describes how the furnace was opened in order to allow the molten iron to drain. You can hear what it was like to actually be there when sparks flew and the iron poured out.

Downcomers I

In making this photograph, I was drawn to the abstract geometric lines and shapes of the pipes, the stairs, and the downcomer itself.

The audio segment describes how the men who worked here were payed not only hourly wages, but also incentive pay to generate more tonnage. The immensity of the work often resulted in the loss of several pounds of body weight per shift. Weight was kept stable with regular meals and the use of salt tablets.

Downcomers II

The furnace downcomers were used to collect the soot, dust, and other furnace waste products.

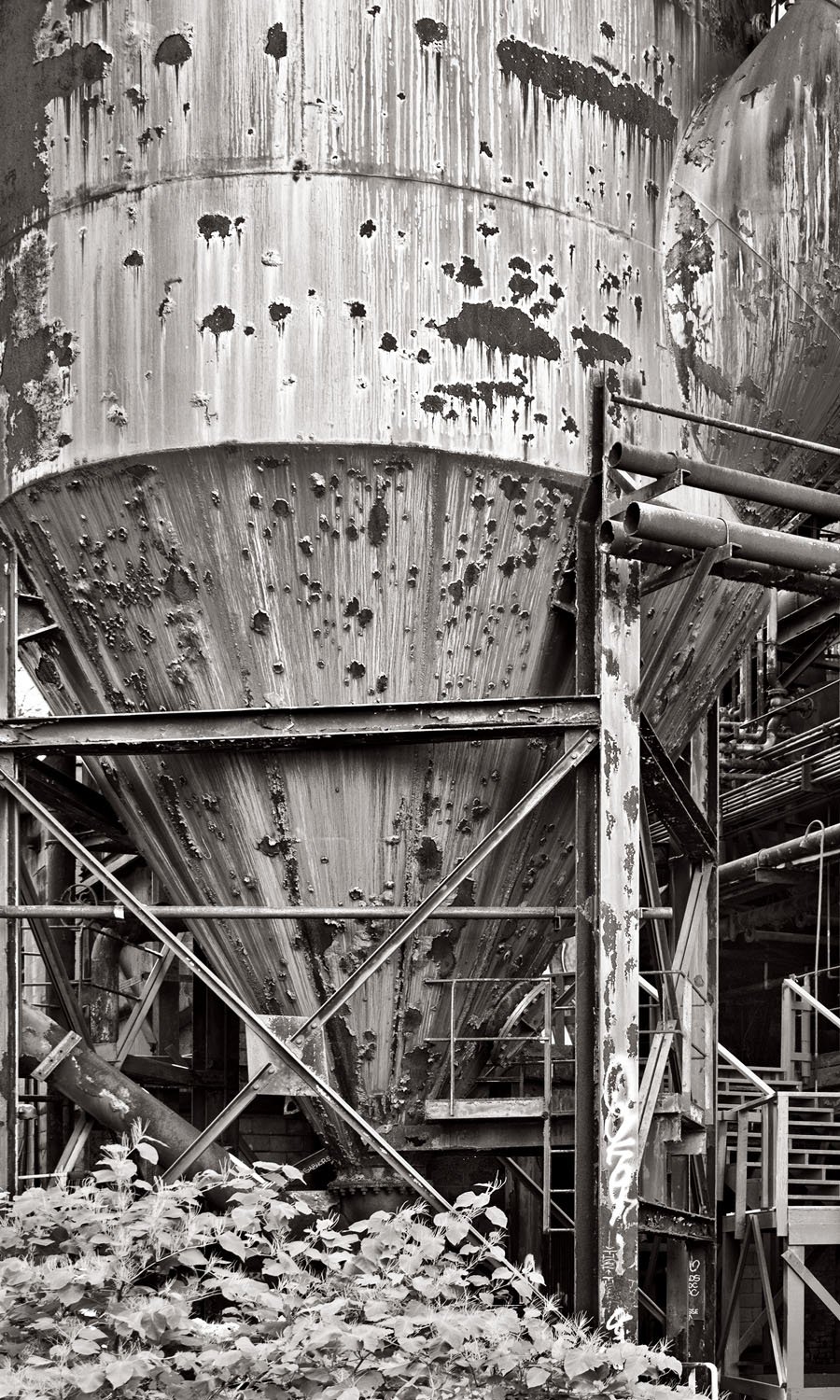

Carrie Furnace II

The large structure towards the back of the image is one of the site's two remaining furnaces. There were once seven such furnaces in use and the facility was able to generate up to 1250 tons of iron on a daily basis.

The audio segment descibes the scene when the furnace was opened at its base and molten iron flowed into the troughs seen in the photo. The molten metal would be directed through the troughs and into 'torpedo cars' which would take the liquid iron across the river to the Homestead Works, where it was used in steel production.

Opening the furnace was a somewhat dangerous event and it was not unusual for the workers shoes to catch on fire. In that case they would simply squirt them down with the nearest water hose, as described in the accompanying audio clip!

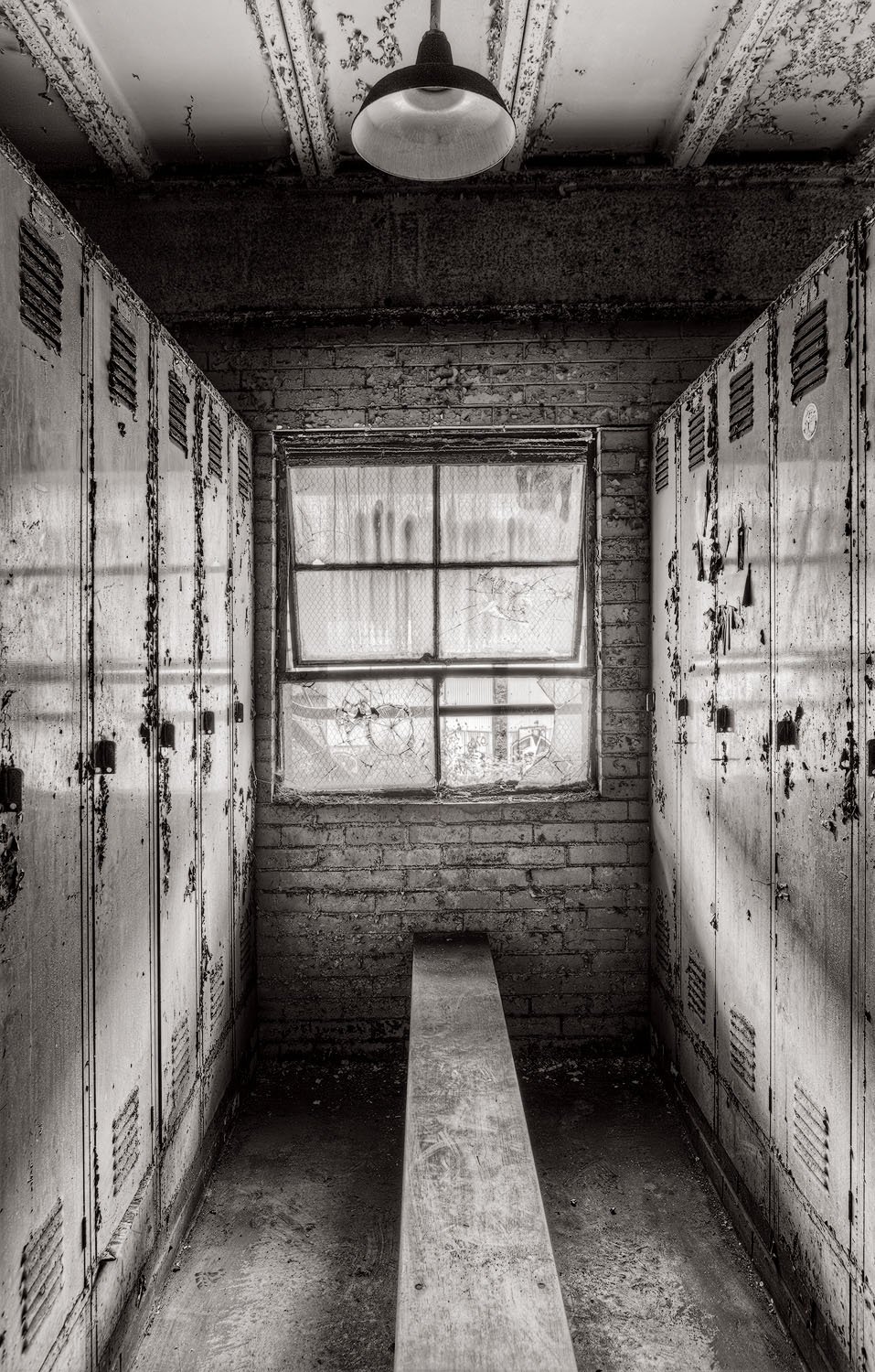

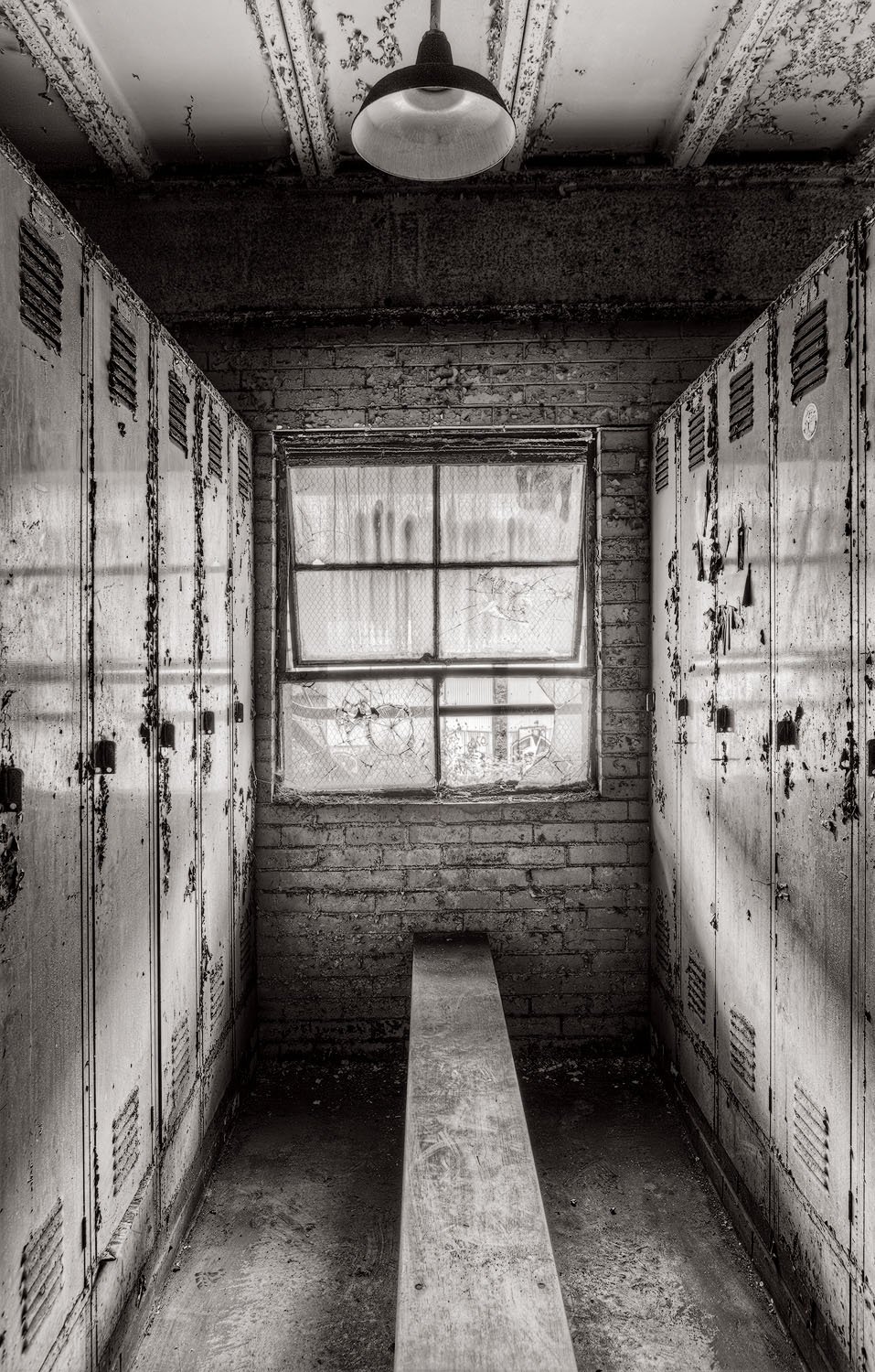

The Locker Room

This was the locker room that Mr. Gault, who was interviewed for this project, used during the years he worked at the Carrie Furnace.

In the audio segment associated with this image he tells how the laborers were not told they were being laid off and were given the impression that they would be back at work in 6 weeks. The workers left personal items in their lockers thinking they would be coming back. Those items were all stolen by vandals years ago and the lockers were barren by the time I arrived.

As Mr. Gault puts it, "everything you owned were in those lockers".

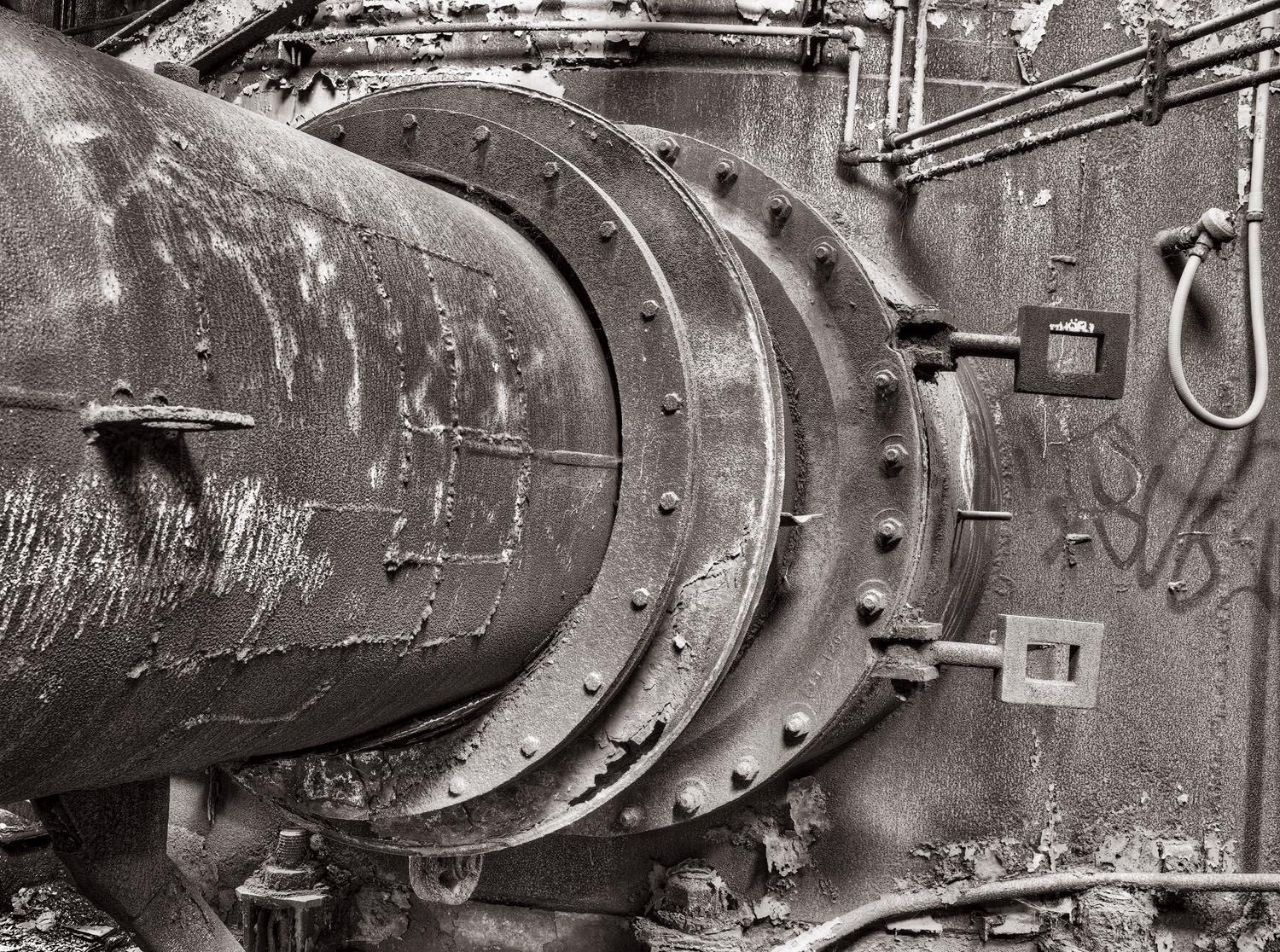

Diamonds

Notice the diamond shapes welded around the circumference of these stove pipes. Despite the amount of work required to cut or burn them out of sheet metal and weld them onto the stoves, they were purely decorative and the stoves would have functioned perfectly well without them. There were several thousand of them throughout the facility and they were made and welded into place as part of the pride that the craftsmen had in their work.

The decorative diamond shapes and the pride they represented to the welders is discussed in this image's audio segment.

Stove Room I

The audio segment associated with this photograph describes how the workers would heat the meals they brought from home on the hot pipes of the furnace. They were always willing to share whatever it was that they had brought from home.

Stove Room II

The audio clip for this image describes what the workers were told when the plant was closed (they were not told that they were being laid off). It also describes how the stoves, as well as most homes in the Homestead area, burned coke gas for fuel instead of natural gas.

Stove Room III

The Stove Room consisted of many of these smaller 'furnaces' in which air was heated to a high temperature and passed on to the main furnace where iron production occurred. The stoves themselves are now covered with graffiti. Nonetheless, the stoves, and their interconnecting network of pipes, make an incredible array of interesting lines and shapes.

The audio segment for this photo describes how the stoves were used.

Stove Room IV

The Stove Room was a dangerous place to work because of the toxic gases that could escape there. For this reason, the workers always entered the Stove Room area in two man teams.

The audio segment describes some of these hazards and how they were dealt with. Anyone for an asbestos suit? Yes, that is one of the the safety precautions that could be taken!

Stove Room V

Despite the fact that when I photographed at the Carrie Furnace it was abandoned and quiet in an almost ghostly sort of way, when it was a functioning mill the noise in the Stove Room was deafening. This is described in the audio segment, where you will hear about how it was so loud that anyone entering had to use hand signals to communicate.

Stove Room VI

Here one sees the massive pipes that were used to feed outside air into the stoves, where it was heated to 1800 degrees.

The audio segment describes how the air was forced into these pipes with large turbines.

Stove Room VII

In making this photograph, I was drawn to the somewhat ominous appearing 'steering wheel' that I presume controlled a valve of some sort. The pathway to it seemed to denote its importance.

In the commentary on a prior image I had lamented that all the stoves were now covered in graffiti. The audio segment for this image describes how, despite the dangers of working in the Stove Room, the room and equipment were kept extraordinarily clean when people worked here.

This photo was selected for publication in the December 2013 Black & White Magazine Single Image Issue.

Chain Valve

The chain seen in this image was used to manually open and close the valves contained within the massive pipes that brought air into the stoves. It would take ten minutes or more to fully open or close the valve.

The audio content describes how this was done by someone who actually spent a good deal of time doing it himself!

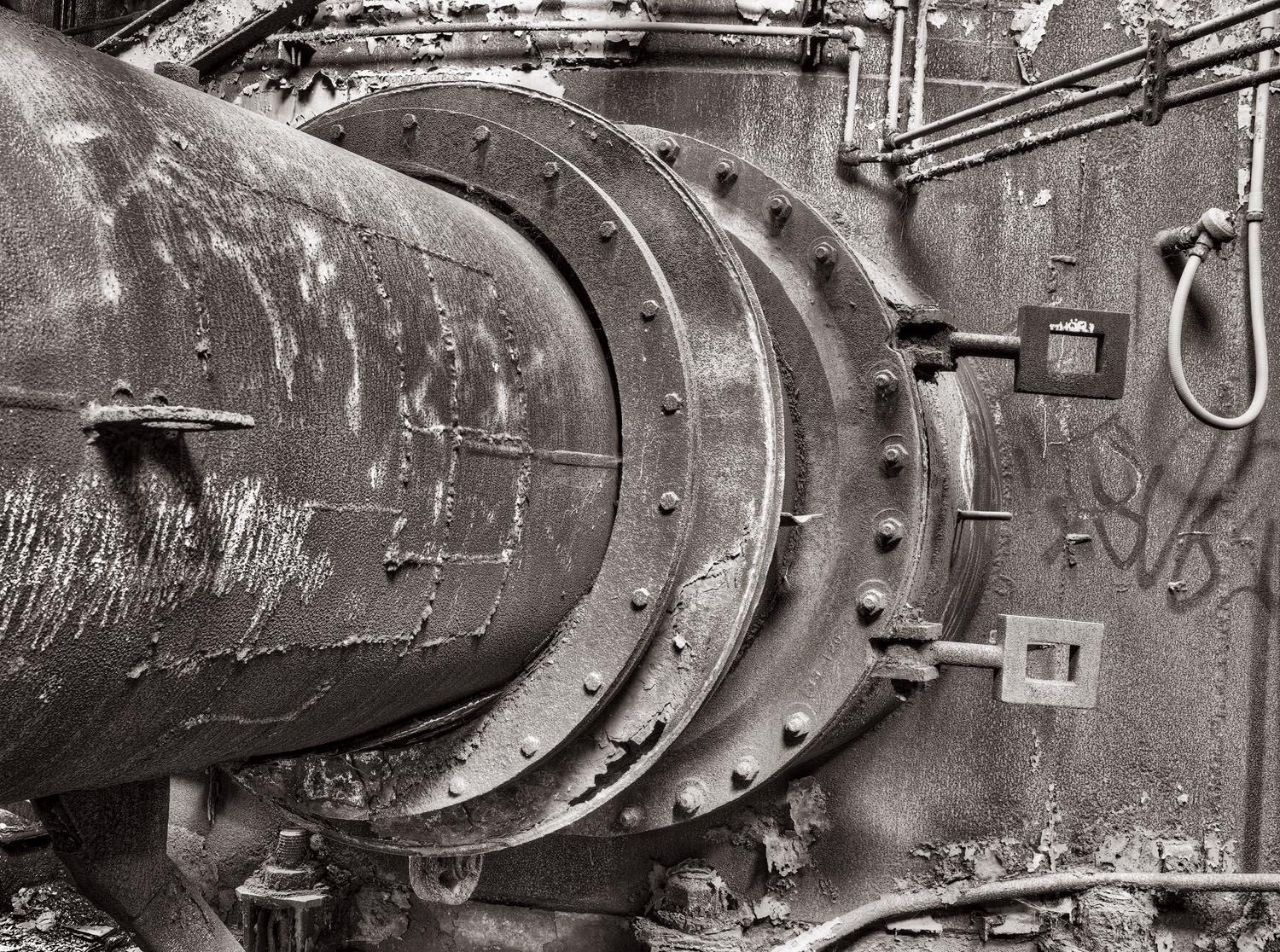

The Latch

I had been wondering for some time about what these star-like metal objects were used for. In the audio segment, Mr. Gault answers that question for me. Can you figure it out before you listen to the audio?

Rivets

The riveted connection of two massive pipes, when isolated from its surroundings, forms an abstract conglomoration of shapes.

Stove Room X

This audio segment has Mr. Gault reminiscing about the past and frankly surprised by the current interest in the furnace, a place where people worked because they had to in order to support themselves and their families. Forty years ago nobody would have been interested enough to have brought a camera into the plant and he himself had no pictures of his old workplace. I gave him some!

Pipes II

In this image I was drawn to the simple, yet beautiful, symmetry of the two pipes that ran in unison.

In the audio segment, one learns that these were welded pipes (the seams can be seen at the elbows), a process that is not routinely utilized in industrial facilities anymore.

Blowdown Pipe

This pipe returned wastewater from the plant back into the Monongahela River. The water being delivered into the river was quite hot and likely played an integral role in the destruction of the river's ecosystem.

The audio content describes this in greater detail.

Elbows

In a dark unlit room that had been the pipe-fitters shop, I ran across a rack of three shelves filled with a stash of these 'elbow pipes' that looked as if no one had touched them since the plant closed in 1978. There they were, just waiting for someone to stick their hand in, grab one, and make good use of it.

It was so dark in the room that I had to frame up what I guessed might be a nice composition, make a long exposure, and see what the results looked like on the LCD of the camera. Then I kept making adjustments until I came up with a composition that seemed to 'work'.

Electrical Cabinets

During my visits to the furnace I ran across this room several times, but on most occasions there was very little light available to make photographs. On this occasion the sun happened to be streaming through the only window in the room, providing a way to photograph the interior. These were apparently electrical cabinets that held circuitry of some sort.

The audio segment associated with this image describes how the current condition of the Carrie Furnace compares to the way it was kept when it was an active mill in the late 1970s. Mr. Gault exprsses what it is like for someone who had worked at Carrie to come back and see it in its present condition.

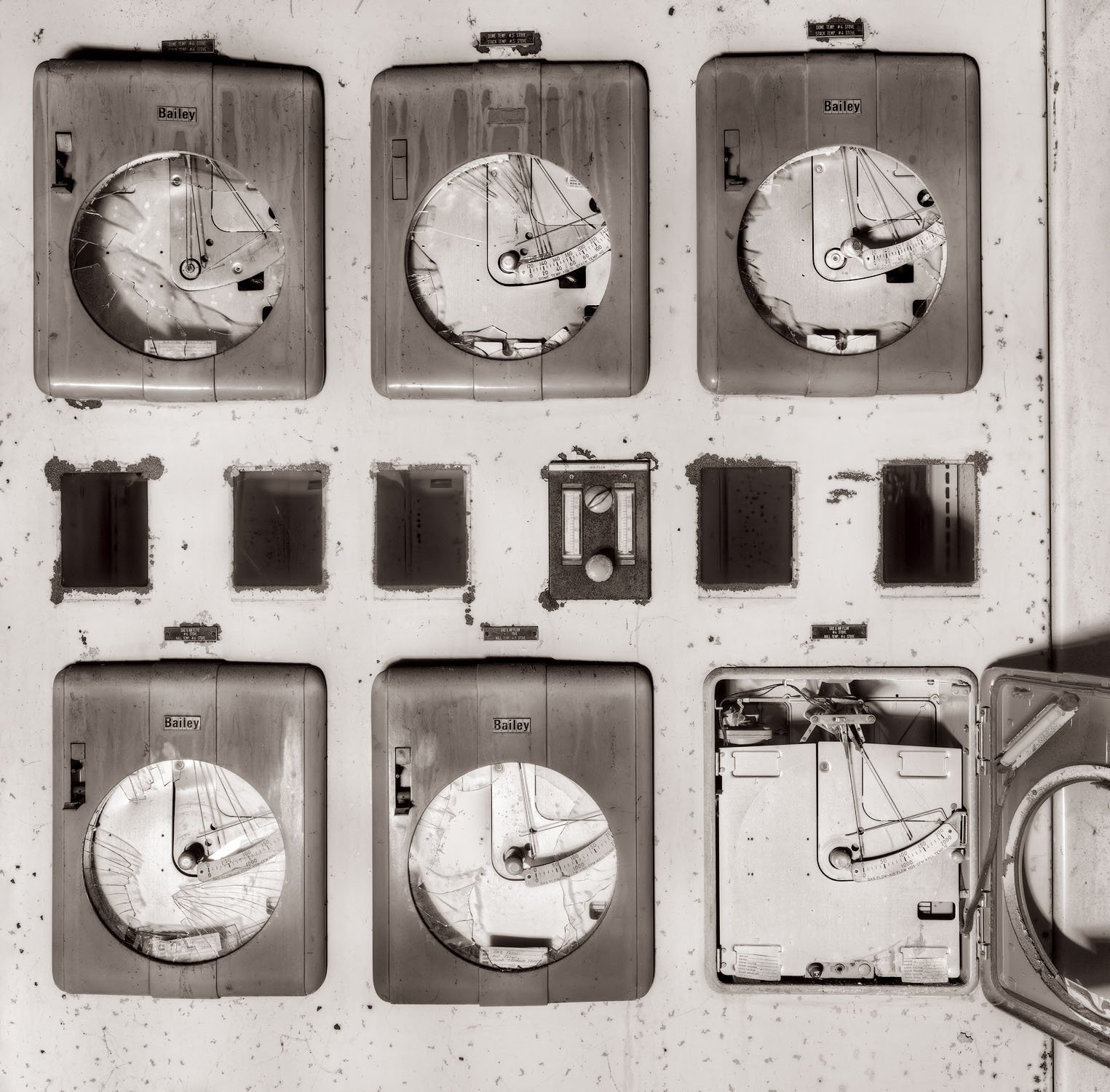

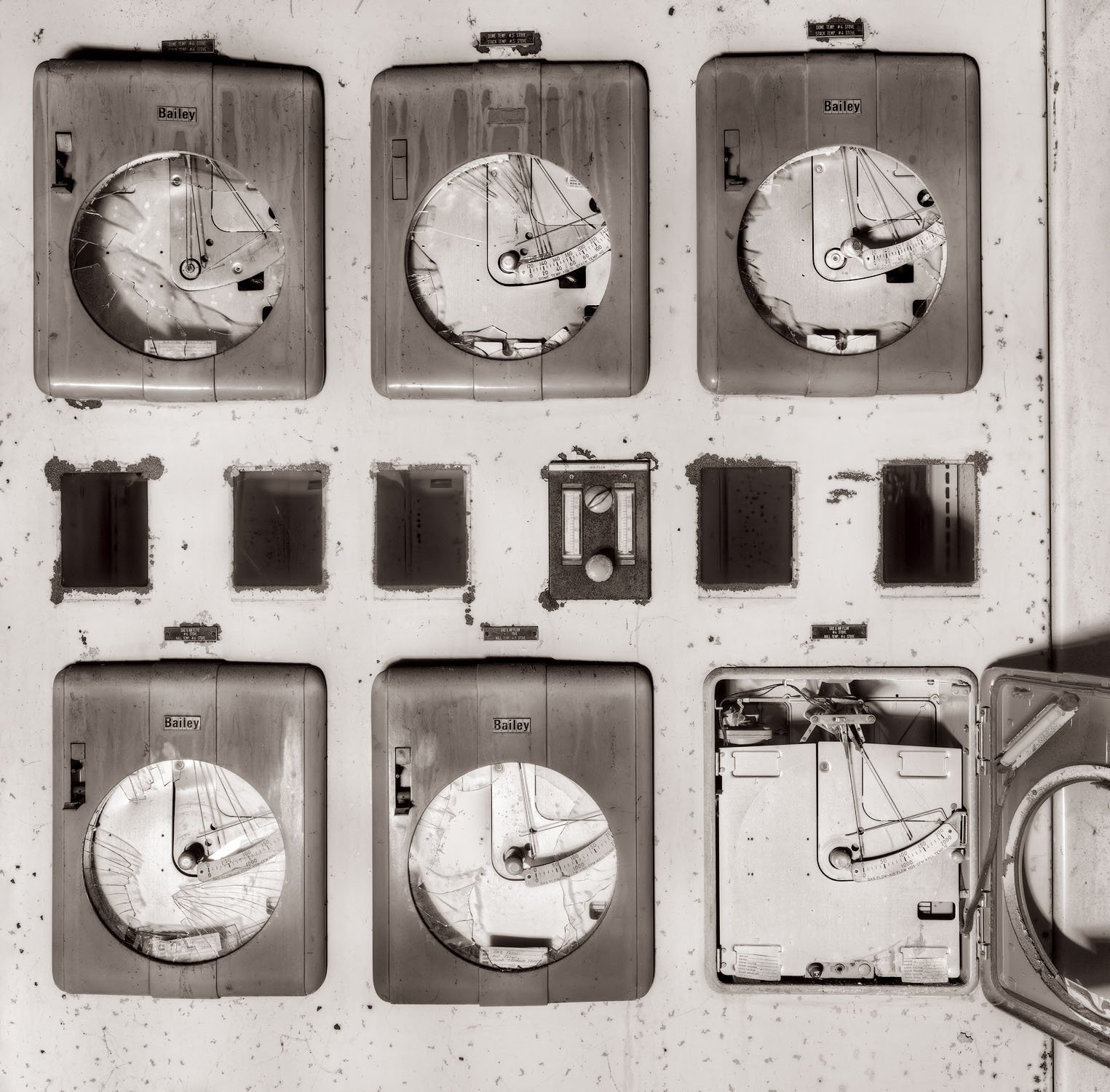

Chart Recorders

This chart recorder was used to constantly monitor the temperature of the stoves, which were used to heat incoming air to approximately 1800 degrees before allowing it to pass into the furnace. It was important that the temperature of the stoves be kept between 1600-1800 degrees. Only supervisors in the stove room were given access to the chart room. Interestingly, since the facility currently has no electricity, this room was pitch dark each time I visited.

I walked into this small room on several occasions and could see absolutely nothing. On one particular day I walked in at exactly the right moment. There was one very small window in the room and the sun was positioned so that it was streaming directly through this window and onto these chart recorders, which I had never been able to see before. I had to work quickly, as I didn't know how long the room would stay lit. About 15-20 minutes later the light was gone, but not before I managed to make this photograph. I have never again seen the room with any light in it!

The audio component describes how the chart recorders were used.

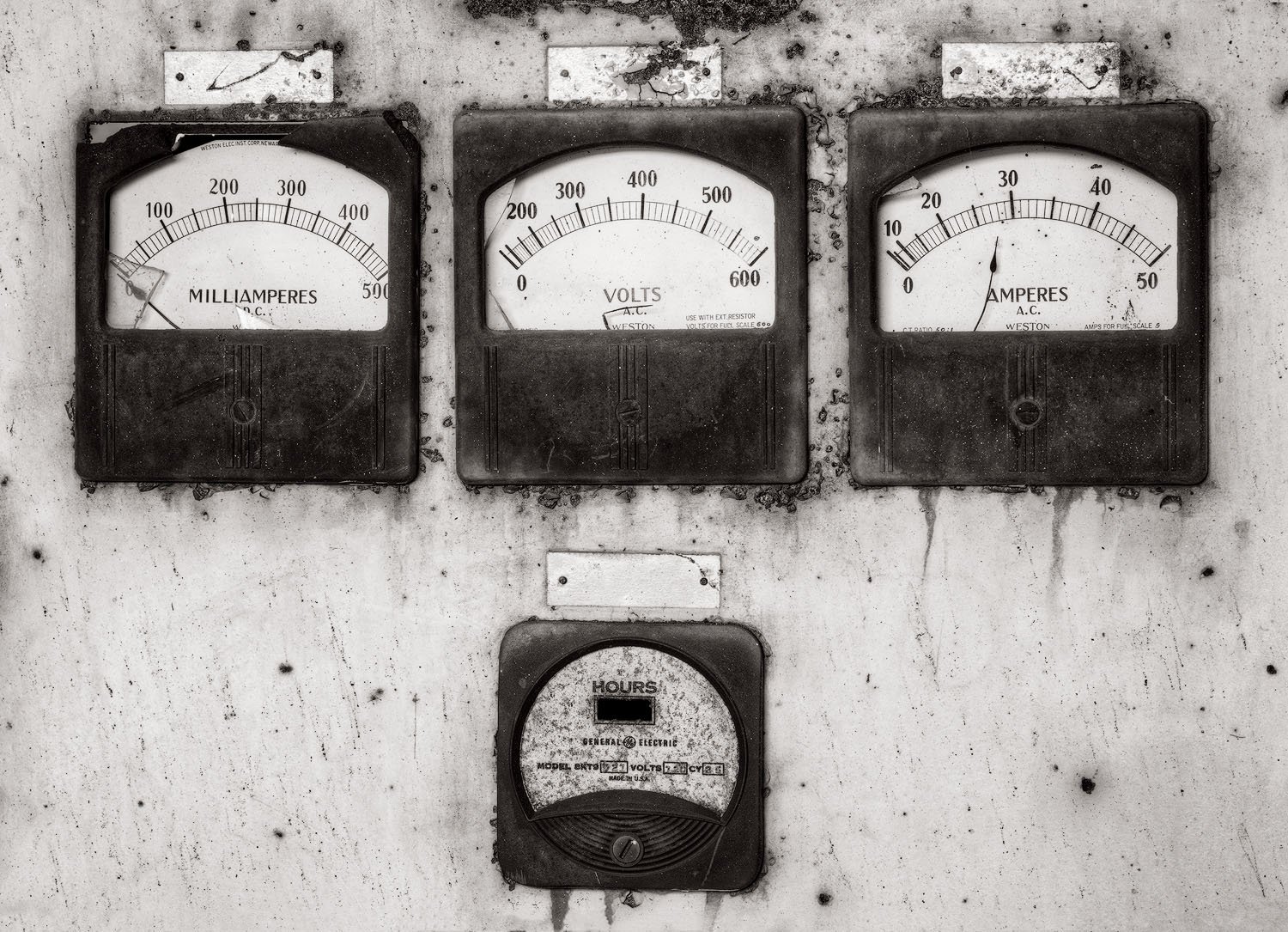

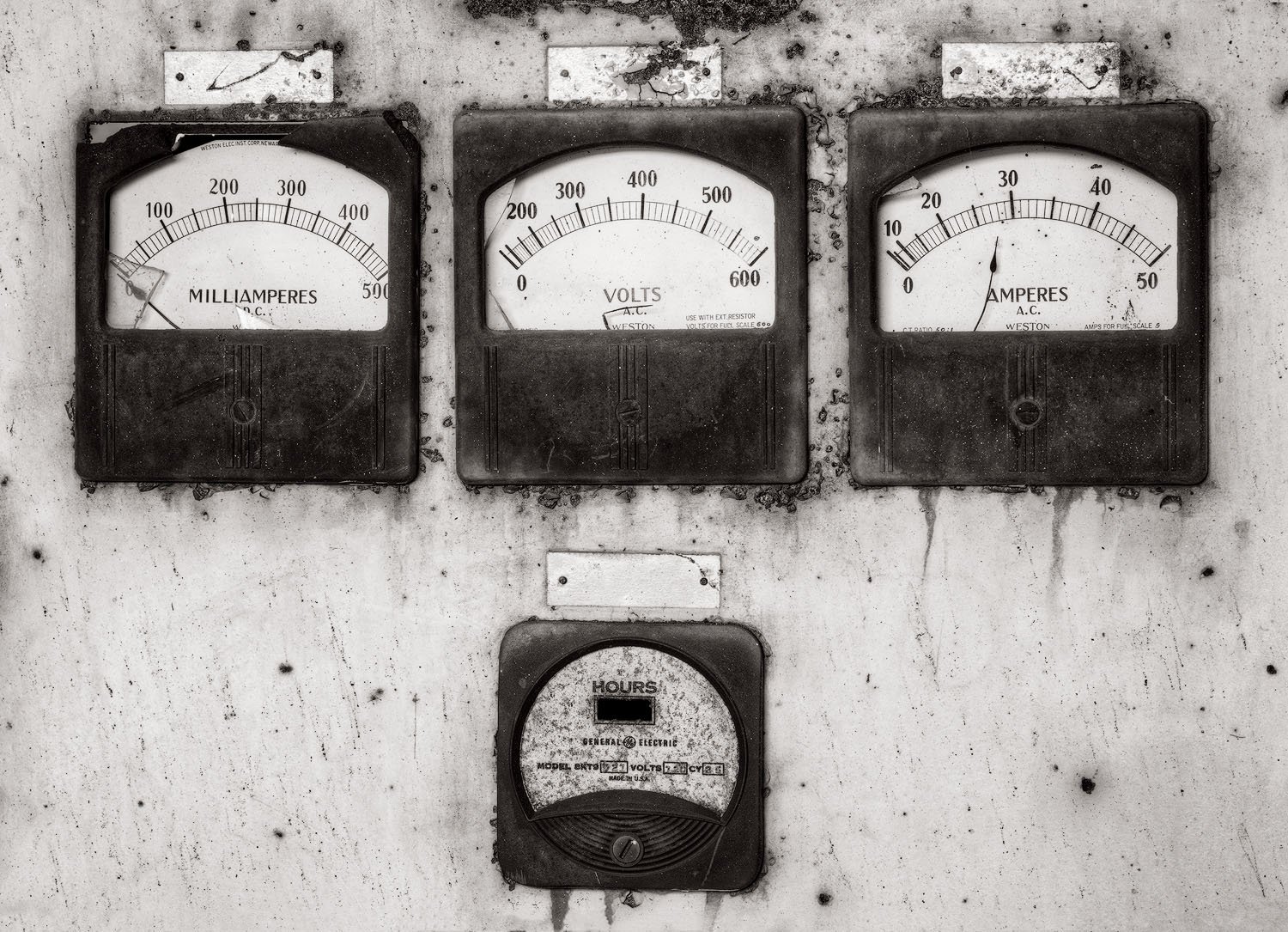

Electrical Panel

There Is No Audio Content For This Image

This image is a close up of the dials and gauges that were on the doors of most of the electrical cabinets. I am uncertain what these guages were used for.

Electrical Box II

When I ran across this old electrical box, it seemed to be perfectly illuminated by the light that was streaming in through a window. This is the type of electrical box that Mr. Gault, who I interviewed for this project, worked on regularly. He recalls these boxes in the associated audio clip.

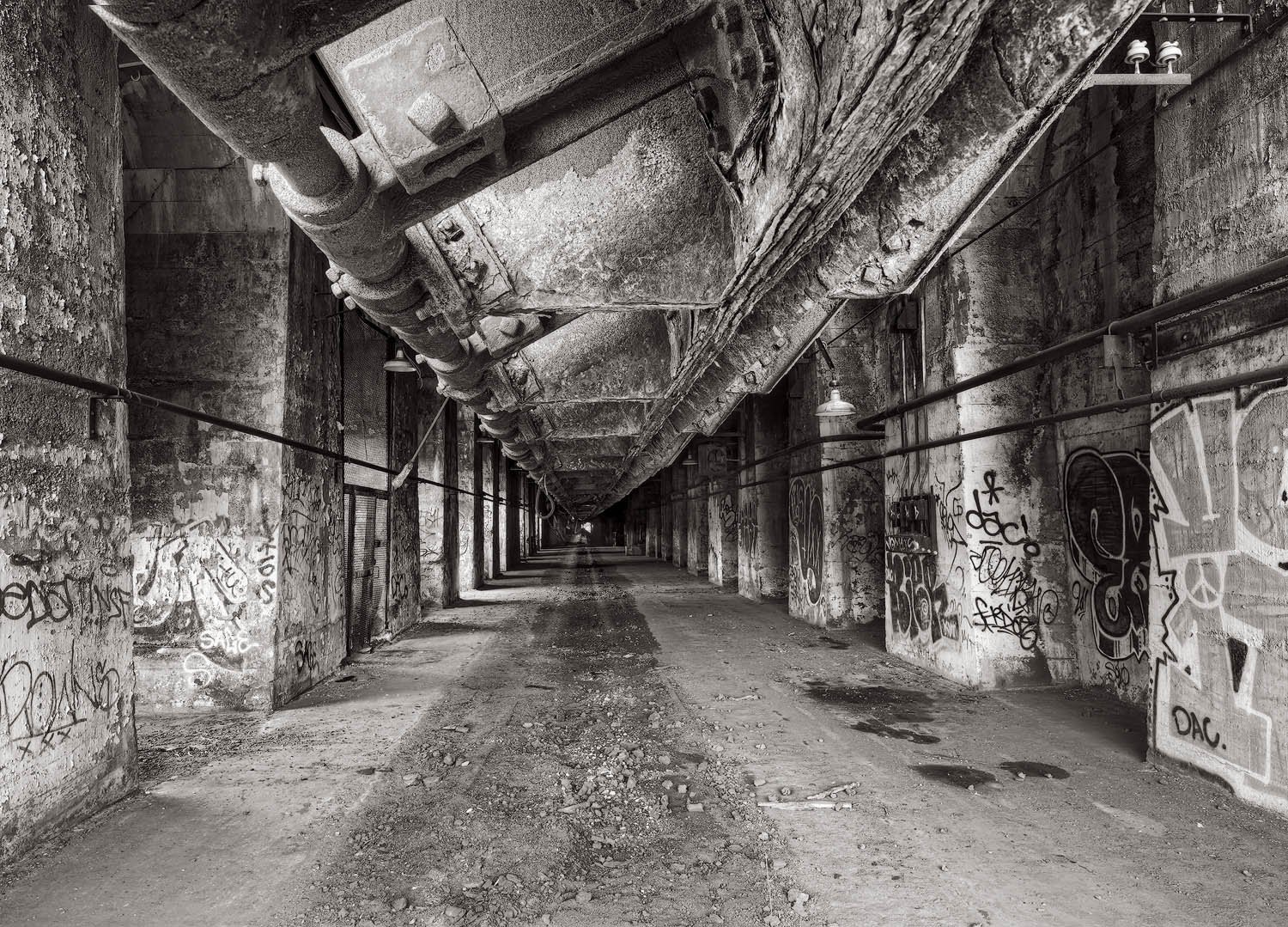

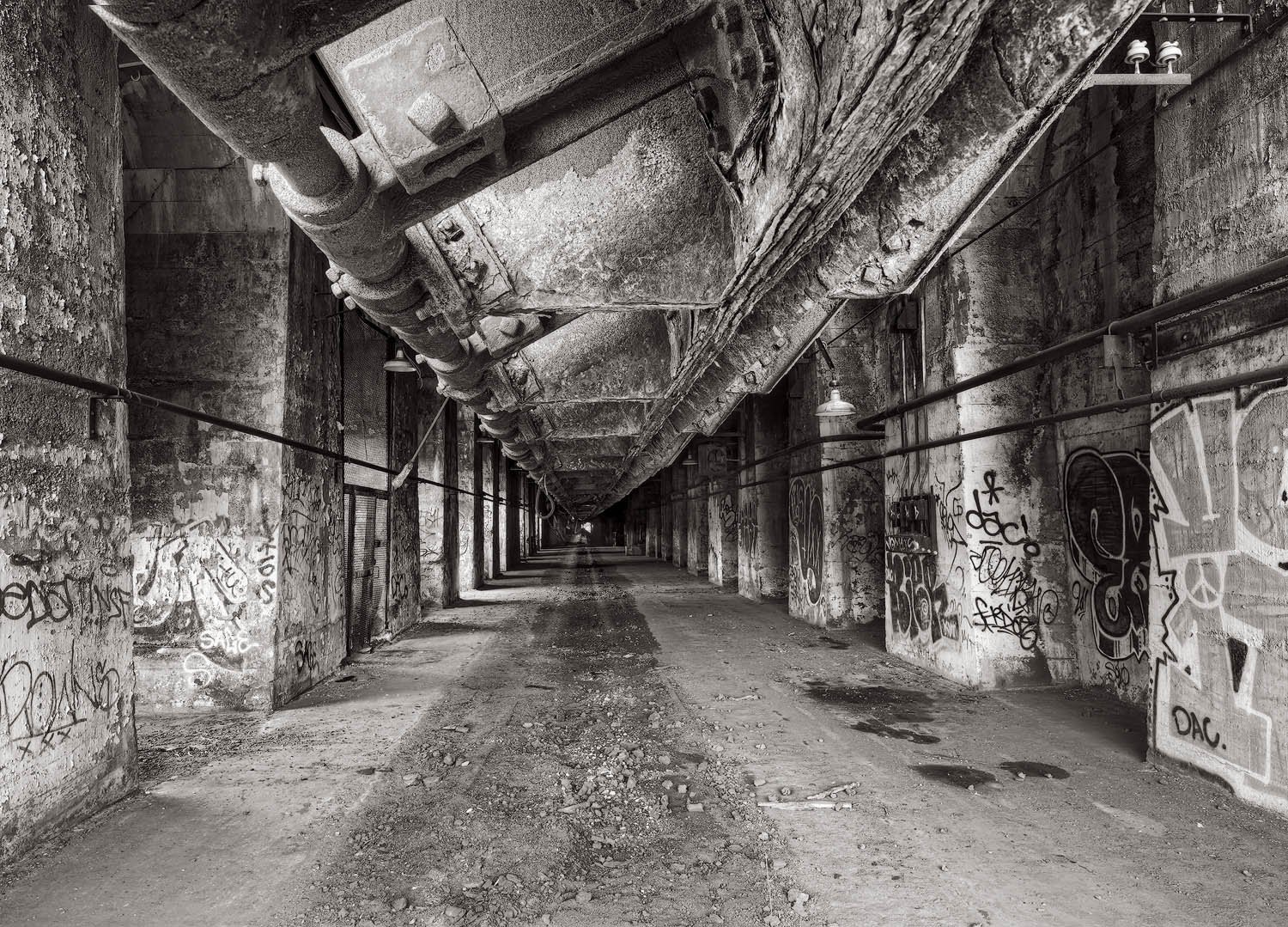

Stock House I

The Stock House was a dark, dreary place that only looks well lit here because the camera's shutter was left open for a full four to five seconds. In the audio segment for this photograph the Stock House is described as a dungeon.

At one time, there were train tracks going through here and so-called "Larry Cars" were driven by the "Larry Men" through the Stock House. The various raw components that were to go into the furnace, such as iron ore, coke, and limestone were stored in massive hoppers, the bottom of which were shaped like a "V". The bottom of the hoppers can be seen as the large metal construction that runs the length of the ceiling of the room in this photo, as well as in "Stock House II".

The Larry Man would drive the Larry Car through the Stock House, stop under the appropriate hoppers, and open them in order to allow specific weights of the various materials to fall into the car. The load was then delivered to the skip car, which would haul the load to the top of the furnace and dump it in.

The process, which required a tremendous amount of brute force to open and close the hoppers, is eloquently described in this photograph's accompanying audio segment as well as in the audio segment for "Stock House II".

Stock House II

Another view of the Stock House, which is described in more detail in the last photograph, Stock House I.

The audio segment continues the eloquent description of what the Stock House was like and what went on there.

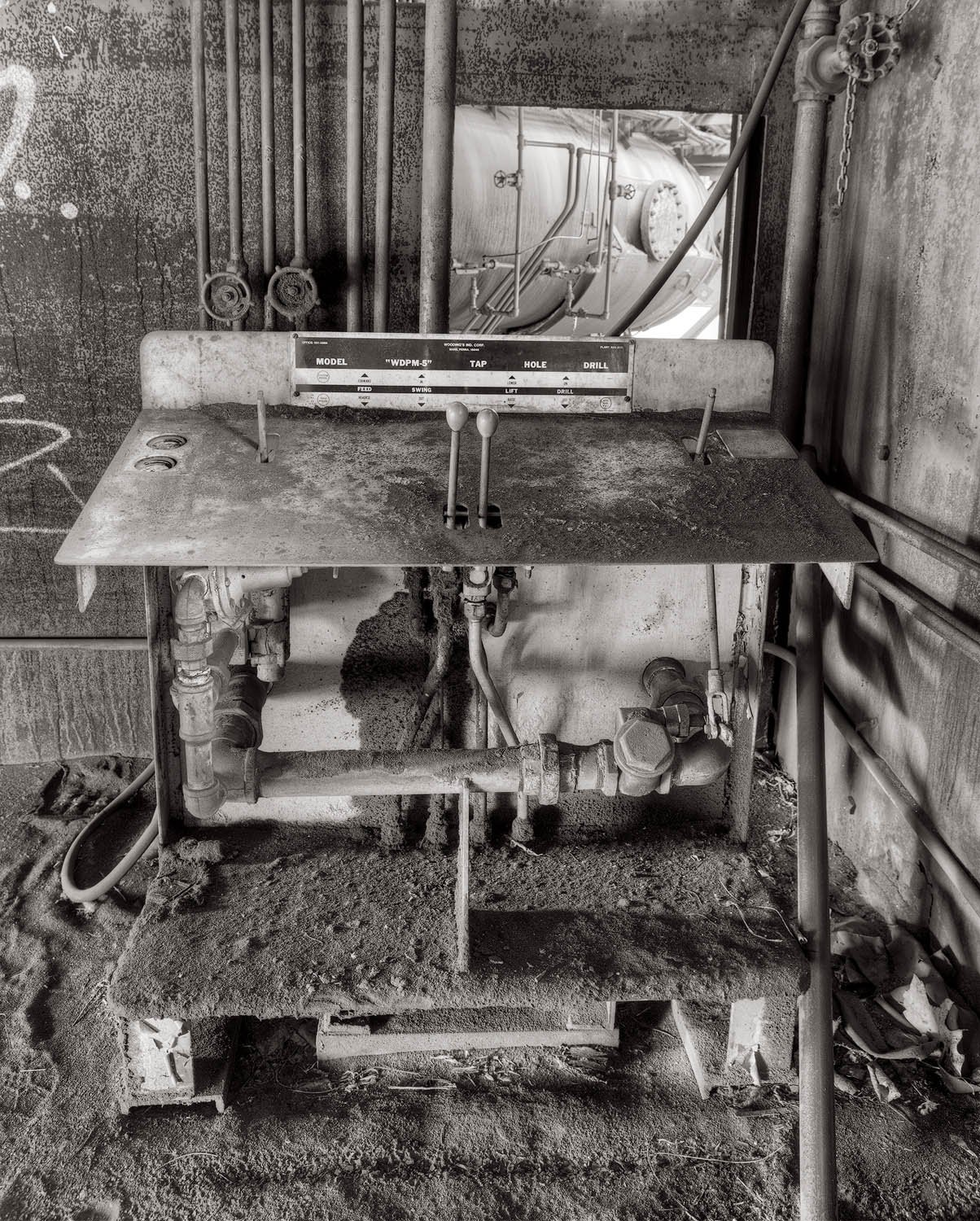

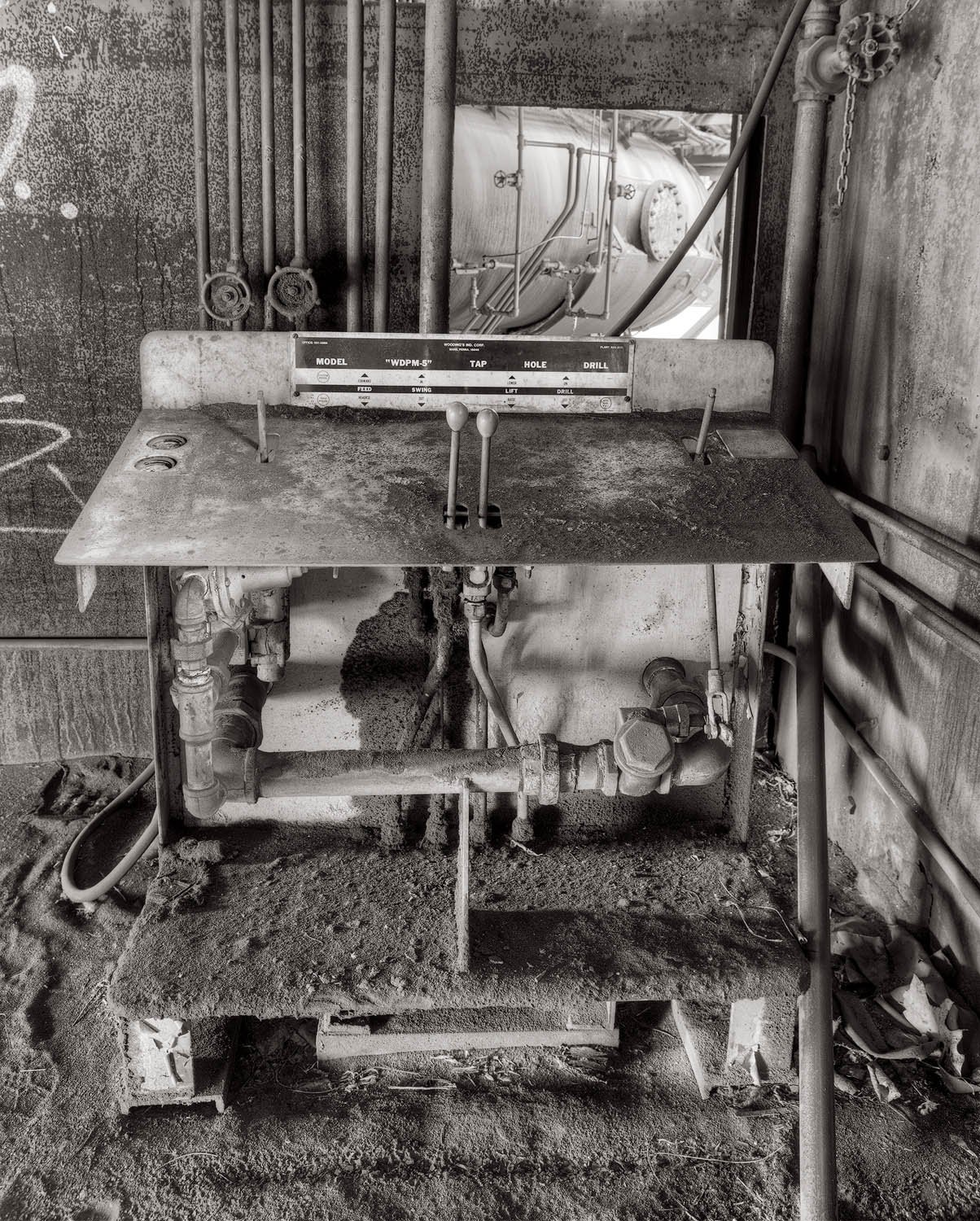

Cast Room Controller

This photograph was taken in a room protected by metal walls. This is where the foreman would use a drill controlled by the device in the photo to open the furnace and drain the molten iron.

The audio segment describes this, as well as how the furnace was closed again after it was drained in order to continue the process of iron production.

Blowing Engine House

This was originally the Blowing Engine House, where massive fans would push air into huge pipes in order to deliver it to the stoves where it was then heated to high temperatures before being routed to the furnace itself. The fans were ultimately replaced with turbines and, when that technology became outdated, this became a shop for blacksmiths, pipefitters, and boilermakers.

The logo on the wall is that of the steel industry and ultimately became used as the emblem for the Pittsburgh Steelers football team.

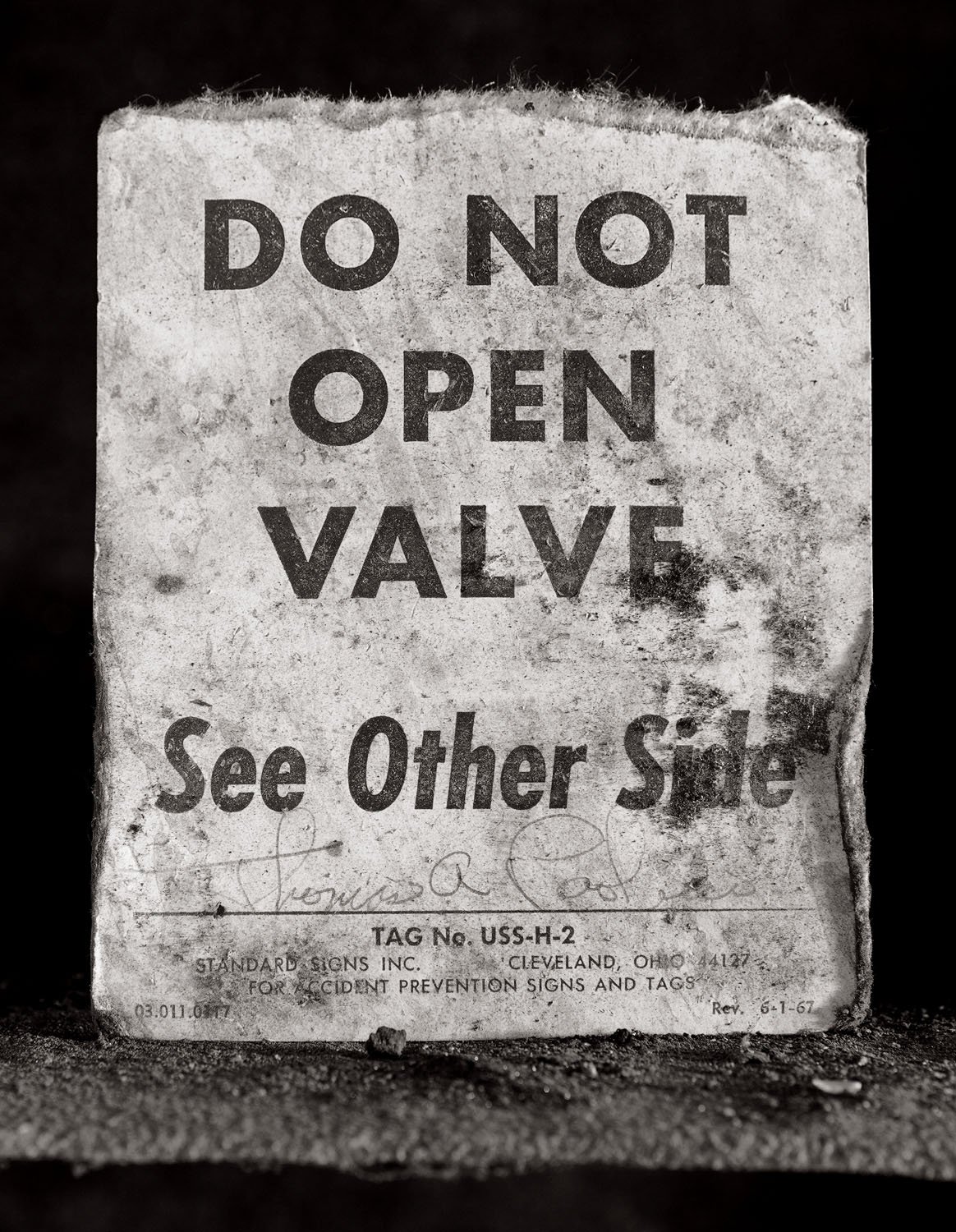

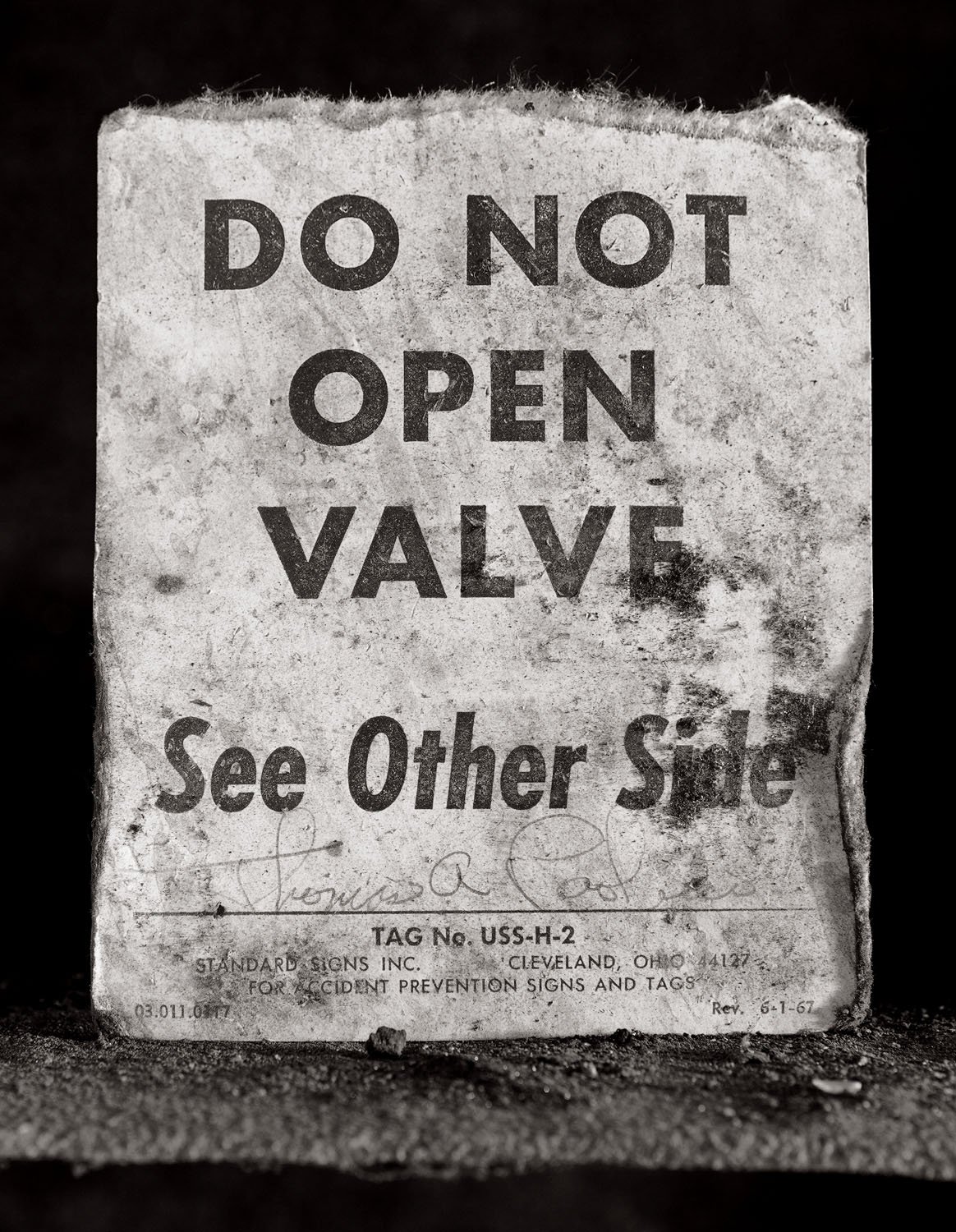

Do Not Open Valve

I found this sign, still intact and displayed, in the Cast Room.

In the audio segment associated with this image, Mr. Gault reminisces about the safety officer who worked at the facility in the late 1970's and whose signature is seen at the bottom of the sign.

Manifold II

There Is No Audio Content For This Image

A close up of one of the many manifolds in the Stove Room.

Solenoid Valves

Solenoid valves found in the Cast Room.

Towers

The audio segment for this image describes how terrifying it was to have to climb these huge towers in order to work on them.

Mr. Gault was affectionately called 'the one handed electrician' because he didn't like heights and would work with only one hand while using the other to hold on for dear life!

The Skip I

This photograph shows one of the 'Skip Cars' that were used to bring raw materials to the top of the furnace, where they were dumped into the fiery iron making process. The four large pipes around the top of the furnace are the 'bleeder valves' used to make adjustments to the pressure in the furnace.

When the furnace wasn't charged correctly it would spew balls of red hot coke into the facility below. The audio segment relates some great anecdotes about what happened when the hot fireballs were released.

The Skip II

The "Larry Men" would use their Larry Cars to transfer the raw materials from the Stock House to these "Skip Cars". These cars would then bring the raw components to the top of the furnace where they would be dumped in. The Skip Cars were in operation 24 hours a day, 7 days a week, 365 days a year unless the furnace was down for repairs or maintenance. There was always a rhythm, with one car going up to deposit its contents into the furnace while the other came down for reloading.

In the audio segment, Mr. Gault recalls what happened when the Larry Man missed while dumping the material from their Larry Car into the skip. Someone had to clean it up!